Polyisoprene Rubber

PROPERTIES:

The synthetic equivalent is polyisoprene (IR) which can be produced by polymerization of 2-methyl-1,3-butadiene with Ziegler-Natta catalyst. Both NR and IR rubbers are often mixed with other ingredients such as oils, fillers, crosslinking agents, and antioxidants, which allows for a versatile variation of the elastomer properties.

Natural and synthetic polyisoprene are inexpensive elastomers with good fatigue resistance and are, therefore, an excellent choice for dynamic applications at low and ambient temperatures. The tensile strength, elongation, and abrasion resistance of natural rubber is excellent over its working temperature range of approximately -50°C to +100°C.

APPLICATIONS :

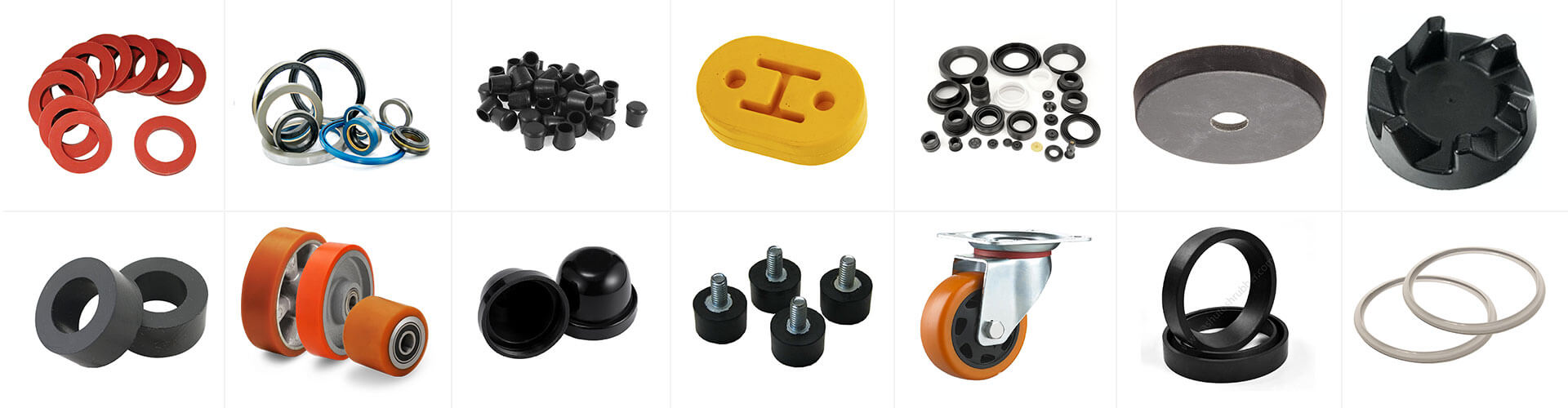

Due to its outstanding strength and excellent compression set, isoprene rubber is the preferred material for many engineering applications. Typical uses include anti-vibration mounts, drive couplings, tires, springs, bearings, rubber bands, and adhesives.

The typical working temperature range is -50°C to +100°C.